Details

Wet Chopped Strands

Chopped Strands for BMC are chopped from E glass BMC fiberglass roving, coated with Silane-based sizing with excellent dry flowability and good dispersion. they are compatible with unsaturated polyester,vinyl ester and epoxy resin systems and designed for compression or injection molding process.

Product Feature

● Good choppability and good gathering

● Good strand integrity and low fuzz

● Low static, excellent mechanical properties

● Excellent pigmental and color matching property

Specification

| Glass Type |

ECR |

|||||

|

Chopped Strands |

CS |

|||||

|

Typical chopped length (mm) |

3,6,9,12,18,24 | |||||

|

Typical Filament Diameter (μm) |

13,33 | |||||

Technical Paramenters

|

Filament diameter variation(%) |

Moisture content(%) |

Sizing content(%) |

Chopped length variation(mm) |

Choppability |

|

ISO1888

|

ISO3344

|

ISO1887

|

Q/JS J0361

|

Q/JS J0362 |

|

±10 |

10.00±2.00 |

≤10.0±0.05 |

±1.50 |

≥ 99.00 |

Applications

Chopped strand for BMC are It widely used in compression molding processes and manufacture various brake shoe facings, clutch facings, friction plates, tanks and sports instruments etc..

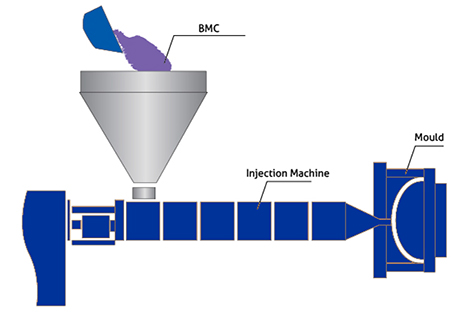

Chopped Strands for BMC Process

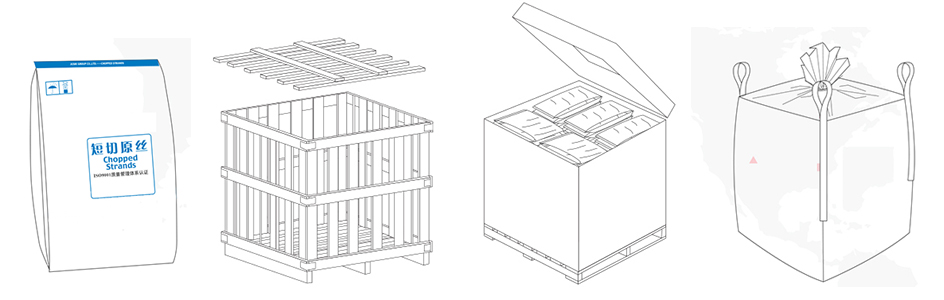

Packing Method

The product can be packed in bulk bags,heavy-duty box, and composite plastic woven bags;

● Composite plastic woven bags can hold 25kg each, Bags size:

|

Length mm (in) |

850 (33.46) |

|

Width mm (in) |

500 (19.69) |

|

Height mm (in) |

120 (4.72) |

● Heavy-duty Box can hold 1000Kg each, Heavy-duty Boxs Size;

|

Length mm (in) |

1030 (40.5) |

|

Width mm (in) |

1030 (40.5) |

|

Height mm (in) |

1050 (41.33) |

● Container bags can hold 900kg-1000kg each, Container Bags Size:

|

Length mm (in) |

990 (38.98) |

|

Width mm (in) |

990 (38.98) |

|

Height mm (in) |

1000 (39.4) |

Storages

Unless otherwise specified, the fiberglass products should be stored in a dry, cool and moisture-proof area. The fiberglass products should remain in their original package until prior to use. The room temperature and humidity should be always maintained at -10℃~35℃ and ≤80% respectively. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, special care should be taken to correctly and smoothly move the top pallet.