Details

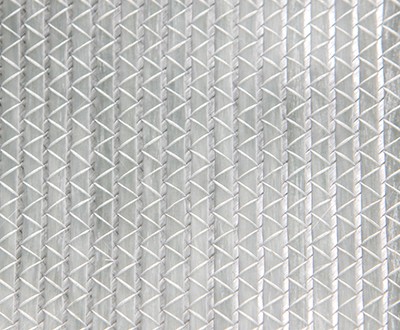

Triaxial (0° 90°/±45° ) Fabrics

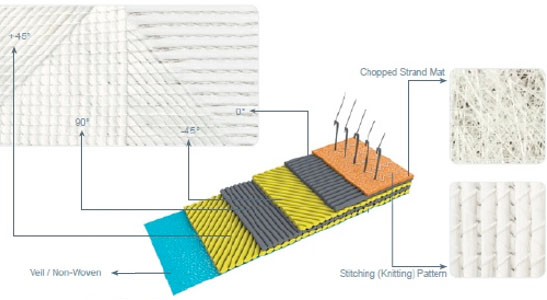

Fiberglass Tri-axial Fabrics are made of E-Glass Roving which is paralleled along 0°/ +45°/-45° or +45°/ 90°/-45° directions and stitched together by polyester yarn.

It can be used to stitch unidirectional layer yarn with chopped strand mat, polyester veil, fiberglass surface tissue, carbon felt etc. into various types of composites fabric to obtain specific performances.

The weight of the warp direction is 150-1200g/m2, the width is from 50-100 inches.

|

Product Code |

Fibers Direction |

|

UDL |

0° Unidirectional Longitudinal Fabrics |

|

UDT |

90° Unidirectional Transverse Fabrics |

|

LT |

0° /90° Warp/Weft Fabrics |

|

BX |

±45° Biaxial or (±30°~89.5°) Fabrics |

|

TXL |

0°±45° Triaxial Fabrics |

|

TXT |

90°±45° Triaxial Fabrics |

|

QX |

0°/45°/-90°/-45°Quadriaxial Fabrics |

Product Feature

● No binder content, good wet out of resin

● Provide mechanical strength of a single direction

● Fiber straight arrangement, max usage of fiber strength

● Interspaces between the fibers are small, effectively improve the impact resistance of products

Specs & Technical

|

Product Code |

Areal Weight (g/m2) |

0° Warp Density (g/m2) |

+45° Density (g/m2) |

90° Weft Density (g/m2) |

-45° Density (g/m2) |

Chopped Strand (g/m2) |

Polyester yarn density (g/m2) |

Layer |

|

TXL600 |

610 |

300 |

150 |

- |

150 |

- |

10 |

3 |

|

TXL750 |

760 |

300 |

225 |

- |

225 |

- |

10 |

3 |

|

TXT750 |

760 |

- |

200 |

350 |

200 |

- |

10 |

3 |

|

TXL900 |

910 |

300 |

300 |

- |

300 |

- |

10 |

3 |

|

TXT900 |

910 |

- |

225 |

450 |

225 |

- |

10 |

3 |

|

TXL1200 |

1210 |

700 |

250 |

- |

250 |

- |

10 |

3 |

|

TXL1200/M300 |

1510 |

700 |

250 |

- |

250 |

300 |

10 |

4 |

|

TXT1200/M300 |

1510 |

- |

250 |

700 |

250 |

300 |

10 |

4 |

Applications

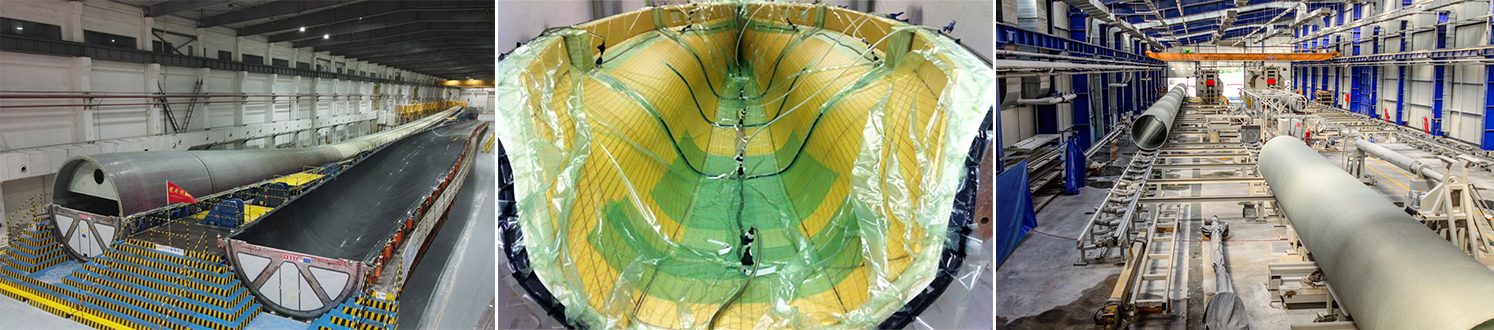

Tri-axial fabrics are compatible with polyester, vinyl ester and epoxy resin. It is designed for pultrusion, filament winding, hand lay-up, vacuum infusion processes. They are widely used in wind blades, shipbuilding, FRP pipes and tanks, marine panels, sports goods, truck panels, automobiles industries etc