Details

Fiberglass Stitched Mat

Fiberglass stitched mat is a mat formed by short-cutting glass fiber roving into a certain length and then spreading it uniformly on a forming mesh belt without orientation, and then stitching it with a loop structure. It can be applied to unsaturated polyester resin, vinyl resin, phenolic resin and epoxy resin, etc.

The mat can be combined with nonwoven surfacing veil (glass surfacing veil in wet processing), Polyester Veil, Polypropylene (PP) cores, or carbon surfacing veil for enhanced performance stitched glass fiber combination mat.

Product Feature

● Excellent compatible with multi-resin

● Good moldability, Good drapability and easy operation.

● Good suitable for hand lay-up, pultrusion, RTM process

● Excellent rollout characteristics and effective reinforcement.

● Completely wet-out and rapid wet through,good transparency of products.

● Fiberglass stitched mat even thickness, high wet tensile strength retention.

Specs & Technical

|

Product Code |

Total

Weigh

(g/m²)

|

Chopped

Strands

(gsm)

|

Stitching

Yarn

(gsm)

|

Moisture

Content

(%) (N/150mm)

|

Combustible Content

(%)

|

Width (mm) |

|

ENC250 |

250 |

240 |

10 |

≤0.2 |

≤5.0 |

200-3200 |

|

ENC280 |

280 |

270 |

10 |

≤0.2 |

≤5.0 |

200-3200 |

|

ENC300 |

300 |

290 |

10 |

≤0.2 |

≤5.0 |

200-3200 |

|

ENC380 |

380 |

370 |

10 |

≤0.2 |

≤5.0 |

200-3200 |

|

ENC400 |

400 |

390 |

10 |

≤0.2 |

≤5.0 |

200-3200 |

|

ENC450 |

450 |

440 |

10 |

≤0.2 |

≤5.0 |

200-3200 |

|

ENC600 |

600 |

590 |

10 |

≤0.2 |

≤5.0 |

200-3200 |

|

ENC900 |

900 |

890 |

10 |

≤0.2 |

≤5.0 |

200-3200 |

Applications

Fiberglass stitched mat is mainly used in pultrusion, RTM, filament winding, compression molding and handlay-up process. Typical products include pultruded parts, pipes, storage tanks, wind generator bladesand other FRP products.

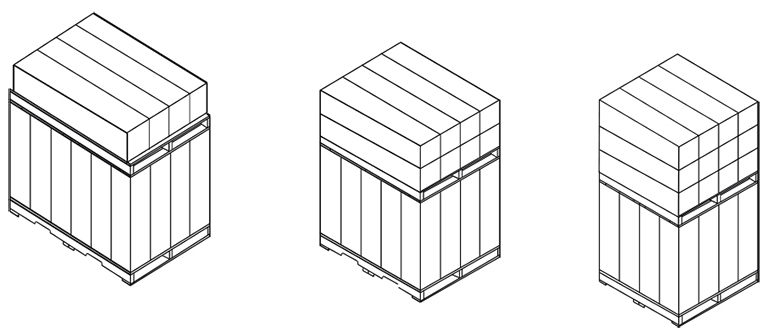

Packing Method

Each roll is wound onto a paper tube which has an inside diameter of 76.2mm(3''). The roll outside diameter is approximately 280mm. Each roll is wrapped up in plastic film and then packed in a carton. The rolls are stacked horizontally or vertically onto pallets. All pallets are stretch wrapped and strapped to maintain stability during transport.

Storage

Fiberglass products should be stored in its original packaging in a dry, cool and water-proof place. The recommended conditions are at temperatures from 15 to 35°C and humidity between 35 and 65%. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high, when the pallets are stacked in 2 or 3 layers, special care should be taken to move the top pallet correctly and smoothly.