Details

Chopped Strand Mat

Continuous Filament Mat (also known as continuous strand mat), is a randomly orientated fiber that differs from chopped strand mat because of continuous long fibers rather than short chopped fibers.

Continuous filament mat is produced bydispensing molten glass strands directly onto a moving belt in a looping fashion. As the glass fiber cools and hardens and a binder is applied to hold the filaments in place. The mat is then trimmed and rolled.

Product Feature

● Good wet out with polyester,epoxy and vinyl ester resins● Not easily move, suit for injection molding

● Easily molding and conforms to complex shapes.

● Excellent compatibility with resin. Conforms to pultrusion process.

● Excellent chemical stability, heating resistance and well insulation.

Specs & Technical

| Product Specification | Stands | CFM225 | CFM300 | CFM450 | CFM600 | CFM900 |

| Fiberglass Type | ISO2078 | E‐glass | E‐glass | E‐glass | E‐glass | E‐glass |

| Sizing | ASTM D578 | Silane | Silane | Silane | Silane | Silane |

| Linear Weigh of Basic Strands (TEX) | ISO1889 | 25 | 25 | 25 | 25 | 25 |

| Unit Weight (g/m2) | ISO3374 | 225 | 300 | 450 | 600 | 900 |

| Tensile Strength (N) | ISO3342 | 70 | 100 | 140 | 160 | 270 |

| Loss on Ignition (%) | ISO1887 | 6 | 5.5 | 4.6 | 4.2 | 3.8 |

| Moisture Content (%) | ISO3344 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

Applications

The continuous filament mats are widely used in auto interior, such as sun visor, rear shelf, spare tire cover, fender, refrigerated carbox, high voltage resistant insulation for transtormers, reinforced profiles, reinforced windows and doors and so on.. It also can beused as reinforced materials in GMT, asphalt linoleum, plastic floor,geotextile. The reinforced products have high product strength, smooth appearance and good moldability.

Continuous filament mat is commonly used in 2 processes: pultrusion and close molding. vacuum infusion, resin transfer molding(RTM), and compression molding.

Packing Method

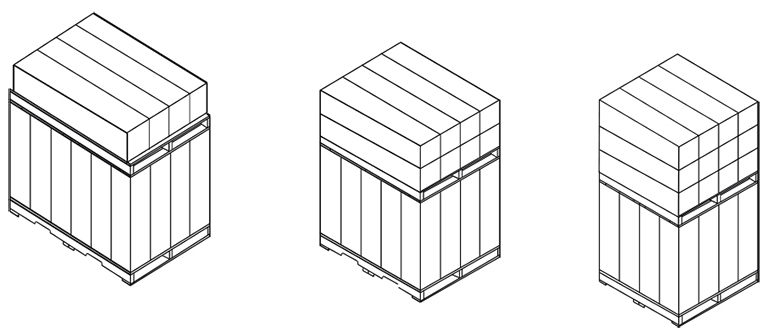

Each roll is wound onto a paper tube which has an inside diameter of 76.2mm(3''). The roll outside diameter is approximately 280mm. Each roll is wrapped up in plastic film and then packed in a carton. The rolls are stacked horizontally or vertically onto pallets. All pallets are stretch wrapped and strapped to maintain stability during transport.

Storage

Chopped strand mat should be stored in its original packaging in a dry, cool and water-proof place. The recommended conditions are at temperatures from 15 to 35°C and humidity between 35 and 65%. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high, when the pallets are stacked in 2 or 3 layers, special care should be taken to move the top pallet correctly and smoothly.