Details

Woven Roving

Fibreglass Woven Roving(Petatillo de fibra de vidrio) is single-end roving in thick fiber bundles that are woven in a 0/90 orientation (warp and weft), like standard textiles on a weaving loom.

Produced in a variety of weights and widths and can be balanced with the same number of rovings in each direction or unbalanced with more rovings in one direction.

Product Feature

● Good chemical resistance

● Excellent electrical insulation

● Even thickness, no fuzz, no stain

● High tensile strength and Fast wet-out

● Uniform density and mechanical properties

● Excellent process ability in the molding process

Specs & Technical

|

Item |

Tex |

Count of

cloth

(root/cm)

|

Unit area mass

(g/m)

|

Breaking

strength

(N)

|

Width

(mm)

|

|||

|

Wrap yarn |

Weft yarn |

Wrap yarn |

Weft yarn |

Wrap yarn |

Weft yarn |

|||

|

EWR200 |

180 |

180 |

6 |

5 |

200+15 |

1300 |

1100 |

30-3000 |

|

EWR300 |

300 |

300 |

5 |

4 |

300+15 |

1800 |

1700 |

30-3000 |

|

EWR400 |

576 |

576 |

3.6 |

3.2 |

400±20 |

2500 |

2200 |

30-3000 |

|

EWR500 |

900 |

900 |

2.9 |

2.7 |

500±25 |

3000 |

2750 |

30-3000 |

|

EWR600 |

1200 |

1200 |

2.6 |

2.5 |

600±30 |

4000 |

3850 |

30-3000 |

|

EWR800 |

2400 |

2400 |

1.8 |

1.8 |

800+40 |

4600 |

4400 |

30-3000 |

Applications

E-glass Fiber Woven Roving is in a variety of resin strengthen systems, and is one of the strongest textile fibers, having greater specific tensile strength than steel wire of the same diameter, at a lower weight.

Woven roving meets hand lay-up, filament winding. Application in boats, vessels, windsurfing, wakeboarding, kayak, jet-ski, wind generator blades., etc.

Packing Method

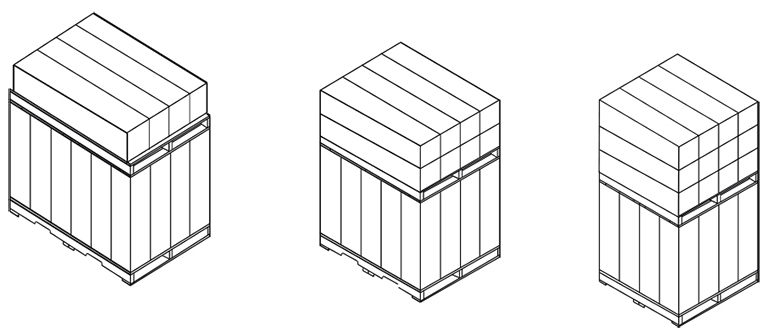

Each roll is wound onto a paper tube which has an inside diameter of 76.2mm(3''). The roll outside diameter is approximately 280mm. Each roll is wrapped up in plastic film and then packed in a carton. The rolls are stacked horizontally or vertically onto pallets. All pallets are stretch wrapped and strapped to maintain stability during transport.

Storage

Fiberglass products should be stored in its original packaging in a dry, cool and water-proof place. The recommended conditions are at temperatures from 15 to 35°C and humidity between 35 and 65%. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high, when the pallets are stacked in 2 or 3 layers, special care should be taken to move the top pallet correctly and smoothly.