Details

Wet Chopped Strands

Wet Chopped Strands is cut the predetermined length from continuous filament strands, The surface is coated with silane-based diffuse lubricant, which is compatible with unsaturated polyester, epoxy and phenolic resin etc. It’s mainly used in the gypsum industry or used as raw materials of fiberglass paper and tissue.

Product Feature

● Good flowability

● Excellent corrosion resistance

● Excellent properties in composite products

● Fast and uniform dispersion in water

Specification

| Glass Type |

ECR |

|||||

|

Chopped Strands |

CS |

|||||

|

Typical chopped length (mm) |

6,13,16 | |||||

|

Typical Filament Diameter (μm) |

6,8,12,18 | |||||

Technical Paramenters

|

Filament diameter variation(%) |

Moisture content(%) |

Sizing content(%) |

Chopped length variation(mm) |

Choppability |

|

ISO1888

|

ISO3344

|

ISO1887

|

Q/JS J0361

|

Q/JS J0362 |

|

±10 |

10.00±2.00 |

≤10.0±0.05 |

±1.50 |

≥ 99.00 |

Applications

Wet Chopped strand for Wet Light Weight Mat is suitable for wet-process thin felt production in white water or pure water systems. Its typical final products include roof waterproofing mat, surface veil, electronicveil, carpet mt and floor mat, etc..

Packing Method

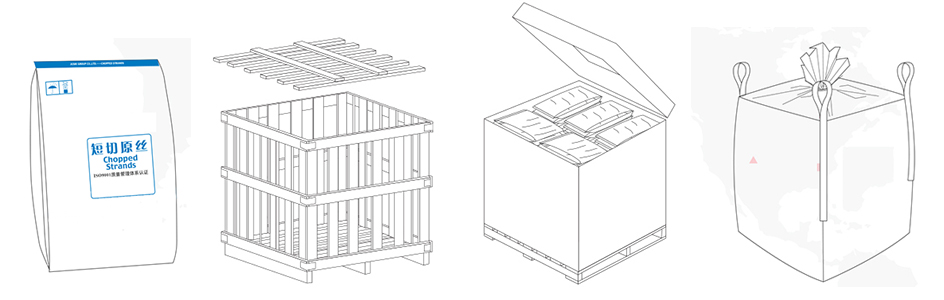

The product can be packed in bulk bags,heavy-duty box, and composite plastic woven bags;

● Composite plastic woven bags can hold 25kg each, Bags size:

|

Length mm (in) |

850 (33.46) |

|

Width mm (in) |

500 (19.69) |

|

Height mm (in) |

120 (4.72) |

● Heavy-duty Box can hold 1000Kg each, Heavy-duty Boxs Size;

|

Length mm (in) |

1030 (40.5) |

|

Width mm (in) |

1030 (40.5) |

|

Height mm (in) |

1050 (41.33) |

● Container bags can hold 900kg-1000kg each, Container Bags Size:

|

Length mm (in) |

990 (38.98) |

|

Width mm (in) |

990 (38.98) |

|

Height mm (in) |

1000 (39.4) |

Storages

Unless otherwise specified, the fiberglass products should be stored in a dry, cool and moisture-proof area. The fiberglass products should remain in their original package until prior to use. The room temperature and humidity should be always maintained at -10℃~35℃ and ≤80% respectively. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, special care should be taken to correctly and smoothly move the top pallet.