Details

Woven Roving Combo Mat

Fiberglass Woven Roving Combo Mat is made by chopped fiberglass strands (50mm in length) randomly dispersed and laid on a roving matrix, andthen knited together by organic fiber (polyester thread). It's compatible with UP, vinyl-ester, phenolic and epoxy resin,

Product Feature

● Excellent pressing performance

● High distributed density & high strength

● Excellent stability & fast wet-out in resins

● Uniform tension, warp and weft yarn even and flat

● Good moldability, fast and wet out completely in resins

● 2 layers fabrics combined improves higher productivity

● Fiber arrayed in high density, easily deformed and operation

Specs & Technical

|

Product Code |

Weight (g/m2) |

Woven

roving

(g/m2)

|

Chopped

strand

(g/m2)

|

Moisture

(%)

|

Layer |

|

EWR200/M200 |

400 |

200 |

200 |

≤0.2 |

2 |

|

EWR300/M300 |

600 |

300 |

300 |

≤0.2 |

2 |

|

EWR400/M300 |

700 |

400 |

300 |

≤0.2 |

2 |

|

EWR500/M300 |

800 |

500 |

300 |

≤0.2 |

2 |

|

EWR500/M450 |

950 |

500 |

450 |

≤0.2 |

2 |

|

EWR600/M300 |

900 |

600 |

300 |

≤0.2 |

2 |

|

EWR600/M450 |

1050 |

600 |

450 |

≤0.2 |

2 |

|

EWR800/M300 |

1100 |

800 |

300 |

≤0.2 |

2 |

|

EWR800/M450 |

1250 |

800 |

450 |

≤0.2 |

2 |

Applications

Fiberglass Woven Roving Combo Mat is compatible with Polyester, Vinyl and Epoxy resin and widely used in boat building, Auto parts, refrigerated tools and structural sections industry etc, suitable for hand lay up, RTM, pultrusion, vacuum processes.

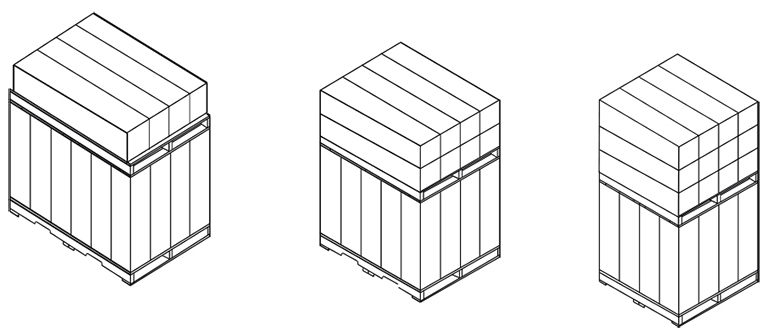

Packing Method

Each roll is wound onto a paper tube which has an inside diameter of 76.2mm(3''). The roll outside diameter is approximately 280mm. Each roll is wrapped up in plastic film and then packed in a carton. The rolls are stacked horizontally or vertically onto pallets. All pallets are stretch wrapped and strapped to maintain stability during transport.

Storage

Fiberglass products should be stored in its original packaging in a dry, cool and water-proof place. The recommended conditions are at temperatures from 15 to 35°C and humidity between 35 and 65%. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high, when the pallets are stacked in 2 or 3 layers, special care should be taken to move the top pallet correctly and smoothly.