Details

Direct Roving For Wind Power

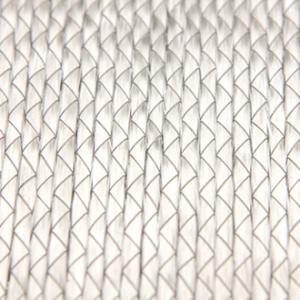

Direct Roving is an alkali-free continuous single-strand direct roving, the surface is coated with silane-based sizing agent. It is suitable for reinforcing unsaturated polyester resin, vinyl resin, epoxy resin and polyurethane resin. It can be used for weaving, filament winding, pultrusion, thermoplastics, wind blades application process.

Product Feature

● High strength and high modulus properties● Good weaving properties and low fuzz

● Rapid and complete wet-out with with epoxy resin and less resin usage

● Excellent acid corrosion resistance and very good aging resistance

● Excellent mechanical properties and good thermal bending resistance

Specification

| Glass Type |

ECR |

|||||

|

Sizing Type |

Silane |

|||||

|

Linear Density (Tex) |

200 | 300 |

600 |

1200 |

2400 |

4800 |

|

Filament Diameter (μm) |

14 |

14 |

16 |

17 |

22 |

25 |

Technical Paramenters

|

Test Sample |

Property | Standard | ECR | High Modulus |

Ultra High Modulus |

| Fiberglass roving | Fiber density (g/cm3) | ISO 1183-1:2019 | 2.655 | 2.586 | 2.595 |

|

Tensile property of impregnated roving, Exoxy resin |

Tensile strength (MPa) | ASTM D2343 | 2500-2700 | 2800-3000 | 3100-3500 |

| Tensile modulus (GPa) |

ASTM D2343 |

81-83 | 89-91 | 95-98 | |

|

1250g/m2 UD fabric, (tested in 0o direction), Iflusion process, Exoxy resin |

Tensile strength (MPa) |

ISO 527-5 | 1076 | 1321.7 | 1332.3 |

|

Tensile modulus (GPa) |

ISO 527-5 |

44.94 |

48.5 | 51.6 | |

| Fiber volume content (%) | ISO 1172 | 55.51 | 53.6 | 53.8 | |

|

Compressive strength (MPa) |

ISO 14126 | 852.45 | 972.8 | 1043.9 | |

|

Compressive modulus (GPa) |

ISO 14126 |

46.18 | 49.1 | 52.1 | |

|

Fiber volume content (%) |

ISO 1172 |

54.89 |

54.4 |

54.2 |

Applications

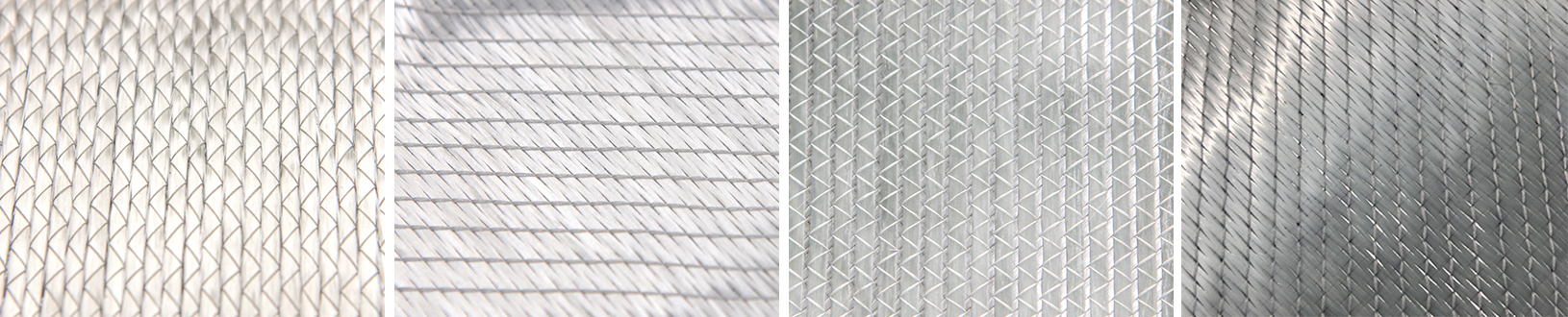

Direct Roving for Wind Power has excellent weaving property and good compatibility with epoxy resin, mainly produce multiaxial fabrics, including Unidirectional Fabric, Biaxial Fabrics, Triaxial Fabric, Quadraxial Fabric and Stitched Mat, due to its ability to meet the requirements of being lightweight, high strength and high modulus properties, It's widely used in wind turbine blades fields.

Unidirectional Fabric Biaxial Fabric Triaxial Fabric Quadraxial Fabric

Packing Method

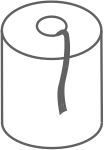

|

Average Coil Weigt—21.5Kg Inner coil diameter—160 mm Outer coil diameter—310 mm Bay height - 260 mm |

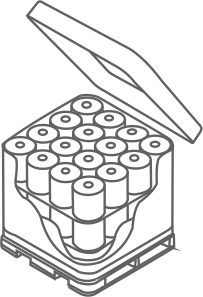

|

Number of coils in a layer — 12 Number of layers — 3 or 4 Net weight of the pallet is about 770 kg or 1040 kg Pallet dimensions — 112 x 112 x 92 cm or 112 x 112 x 118 cm (L x W x H) |

|

Storage

The fiberglass products should be stored away from heat and moisture, and in their original packaging. The best conditions are: temperatures between -10 ºC and 35 ºC; humidity between 35 and 65 %. If the product is not stored under these specifications, it is advisable to condition it in the workshop for at least 24 hours before use, to prevent condensation.

To ensure safety and avoid damage to the product, the pallets should be stacked not more than three layers high. When the pallets are stacked in two or three layers, special care should be taken to correctly and smoothly move the upper pallet.