Details

Unidirectional Warp 0° Fabrics

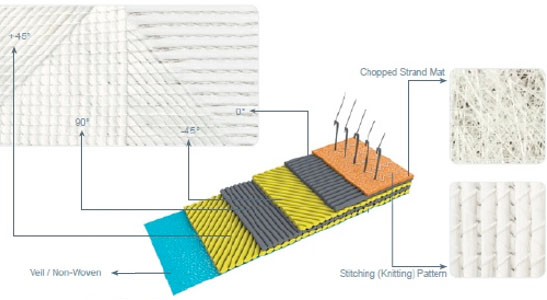

Unidirectional Warp 0° Fabrics based on 0°weight and 90°weight as supplement which is usually 100% weight of 0° weight, and stitched with a coil structure. attaching (50-500)g/m2 CSM or Nonwoven fabric on the bottom. It can be used to stitch unidirectional layer yarn with chopped strand mat, polyester veil, fiberglass surface tissue, carbon felt etc. into various types of composites fabric to obtain specific performances.

The weight of the warp direction is 150-1200g/m2, the width is from 50-100 inches.

|

Product Code |

Fibers Direction |

|

UDL |

0° Unidirectional Longitudinal Fabrics |

|

UDT |

90° Unidirectional Transverse Fabrics |

|

LT |

0° /90° Warp/Weft Fabrics |

|

BX |

±45° Biaxial or (±30°~89.5°) Fabrics |

|

TXL |

0°±45° Triaxial Fabrics |

|

TXT |

90°±45° Triaxial Fabrics |

|

QX |

0°/45°/-90°/-45°Quadriaxial Fabrics |

Product Feature

● No binder content, good wet out of resin

● Provide mechanical strength of a single direction

● Fiber straight arrangement, max usage of fiber strength

● Interspaces between the fibers are small, effectively improve the impact resistance of products

Specs & Technical

|

Product Code |

Areal Weight (g/m2) |

0° Warp Density (g/m2) |

Chopped Strand (g/m2) |

Polyester Veil (g/m2) |

Polyester yarn density (g/m2) |

Layer |

|

UDL336 |

346 |

336 |

- |

- |

10 |

1 |

|

UDL400 |

410 |

400 |

- |

- |

10 |

1 |

|

UDL400M225 |

635 |

400 |

225 |

- |

10 |

2 |

|

UDL400P30 |

440 |

400 |

- |

30 |

10 |

2 |

|

UDL600 |

610 |

600 |

- |

- |

10 |

1 |

|

UDL800 |

810 |

800 |

- |

- |

10 |

1 |

|

UDL900 |

910 |

900 |

- |

- |

10 |

1 |

|

UDL1200 |

1210 |

1200 |

- |

- |

10 |

1 |

Applications

0° Warp Unidirectional Fabric has properties of ease of handling and cutting, high strength and quick wet out, stability, stiffness.This fabric is suitable for the Polyester resin, Vinyl resin, Epoxy resin, Phenolic resin etc.

It is used in length directional reinforcement or ring turns reinforcement, vane of the wind power, bridge, pillar reinforcement and so on.