Details

Chopped Strand Mat

Chopped Strand Mat (CSM) is a form of reinforcement material commonly used in the composite industry, particularly in fiberglass manufacturing. It is made from short strands of glass fibers that are randomly oriented and typically held together by a binder, which allows the mat to conform to various shapes during the molding process. This material is primarily used in hand lay-up processes and in processes involving light machinery to produce a wide range of products.

Product Feature

● Fast breakdown in styrene● Superior acid corrosion resistance

● Good wet-through and fast wet-out in resins, rapid air lease

● High tensile strength, allowing for use in hand lay-up process to produce large-area parts

Specs & Technical

|

Chopped Strand Mat for Transparent Panel |

|||

|

Powder Type |

|||

|

Specs |

Tensile Strength(N) |

Loi content(%) |

Moisture (%) |

|

200g |

80-100 |

3.5-4.5 |

≤0.1 |

|

225g |

90-110 |

3.0-4.2 |

≤0.1 |

|

250g |

100-120 |

2.9-4.0 |

≤0.1 |

|

300g |

110-130 |

2.8-3.2 |

≤0.1 |

|

350g |

130-150 |

2.7-3.1 |

≤0.1 |

|

380g |

135-155 |

2.6-3.0 |

≤0.1 |

|

400g |

140-160 |

2.6-3.0 |

≤0.1 |

|

450g |

170-190 |

2.5-2.8 |

≤0.1 |

Applications

The sliane sizing system of basic strands and the nature of the binder make CSM suitable for use with epoxy, vinylester and UP resins in the following applications: automotive, trucks, sport and leisure, urban, industrial and marine parts, etc.

It is used for the manufacturing of FRP tiles, FRP plates and those that have a need for light. The product has high tensile strength and can meet the requirements for machine-made or hand lay-up technique.

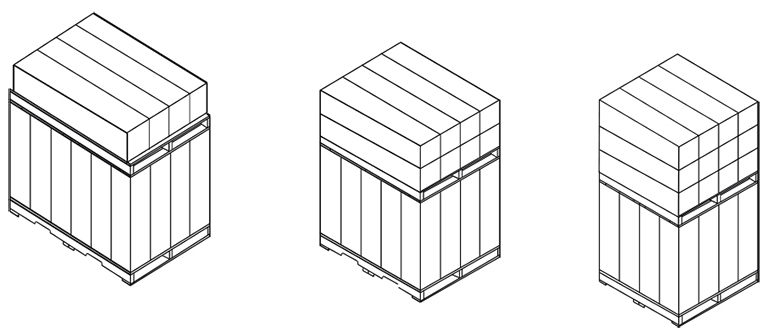

Packing Method

Each roll is wound onto a paper tube which has an inside diameter of 76.2mm(3''). The roll outside diameter is approximately 280mm. Each roll is wrapped up in plastic film and then packed in a carton. The rolls are stacked horizontally or vertically onto pallets. All pallets are stretch wrapped and strapped to maintain stability during transport.

Storage

Chopped strand mat should be stored in its original packaging in a dry, cool and water-proof place. The recommended conditions are at temperatures from 15 to 35°C and humidity between 35 and 65%. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high, when the pallets are stacked in 2 or 3 layers, special care should be taken to move the top pallet correctly and smoothly.